PVD Coated Grades for Turning and Parting Stainless Steel, Heat-Resistant Alloy and Steel

Grade Description: Nano-structured nc-TiAlN (PVD) coated carbide (nano coating grade)

| Nano PVD TiAlN coating with ultrafine microstructure on high-strength carbide substrate |

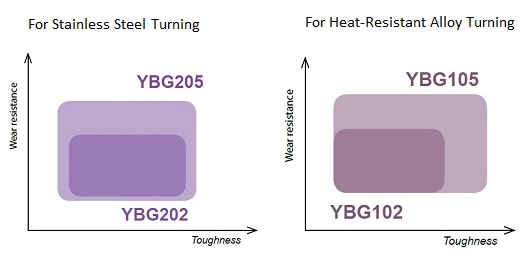

This TiAlN nano coating grade with fine-grained carbide offers highly smooth insert surface, and has excellent high temperature wear and adhesion resistance. Inserts in this grade with NF and NM chipbreakers are suitable for finishing to semi-finishing of heat-resistant alloys, respectively.

This TiAlN multilayer nano coating grade with ultrafine-grained carbide offers high wear and high-temperature oxidation resistance, and higher toughness than YBG102. Inserts in this grade with NF and NM chipbreakers are excellent choices for finishing to semi-finishing of heat-resistant alloys, respectively.

This TiAlN nano coating grade has ultra-fine grain tungsten carbide substrate. The great wear and buildup resistance makes this grade a versatile one for finishing to medium machining of a wide range of materials, particularly steels, stainless steels and heat-resistant alloys.

This TiAlN nano coating grade with special surface treatment and highly engineered carbide substrate has combination of high hardness and excellent heat resistance. Strong bonding of the coating to the carbide protects cutting edge integrity. Inserts of grade are recommended as the first choice for stainless steel turning, parting and grooving of steels and stainless steel in small workpieces, particularly for those that require high surface finish.

The combination of nc-TiAIN coating and tough cemented carbide substrate, which integrates security and wear resistance, makes it primary grade for parting and grooving of various materials (steels, stainless steels, cast iron and heat resistant alloys).

Nano-TiAIN PVD coating on high strength fine carbide substrate. The new coating technology increases the coating/substrate bonding that results in excellent combination of toughness and hardness. As an enhancement to Grade YBG202 and YBG205, inserts of this grade are suitable for turning of a variety of materials, especially stainless steels and heat-resistant alloys.

With the new nano-TiAlN coating on the fine and uniform carbide substrate, this grade offers excellent resistance against high temperature oxidation, wear and edge built-up. It is ideal for turning operation of difficult-to-machine materials such as Inconel 718 superalloy.